During the interruption process of switching devices, electric arc phenomena can easily occur, causing damage to the equipment and system. The SF6 gas circuit breaker is prioritized in these cases to extinguish the arc quickly. So, what is an SF6 circuit breaker? Let Etinco find out about the structure, working principle, and application of this switching device in the article below.

Concept of SF6 Circuit Breaker

The SF6 circuit breaker or Sulfur Hexafluoride circuit breaker is a switching device for high-voltage electrical circuits in all operating modes: no-load mode, rated-load mode, and fault mode, aiming to ensure the safety of medium-to-high voltage power transmission and distribution systems from short circuit and overload conditions. In particular, this switching device is used to effectively and completely extinguish the electric arc in power plants and power grids.

The SF6 circuit breaker uses SF6 gas as the insulating medium to extinguish the arc. Compared to insulating substances like air, oil, and vacuum, SF6 has superior dielectric strength and thermal stability. Notably, SF6 is non-flammable, non-toxic, and capable of rapid arc extinction due to its effective heat transfer properties and very high electronegativity. SF6 has a strong tendency to absorb free electrons from the arc when discharge occurs between the contacts, subsequently creating resistance across the contacts, and finally suppressing the arc. After the arc is extinguished, the SF6 gas regenerates almost immediately to further de-ionize the contacts and establish the necessary insulating environment to prevent reignition.

In reality, oil-quenched circuit breakers have been used since the 20th century for medium-voltage distribution systems in medium-voltage switchgear. However, this type of arc extinction has major drawbacks such as fire hazard and high maintenance costs. The introduction of the SF6 circuit breaker not only replaced outdated circuit breakers in the electrical industry, such as oil circuit breakers and air circuit breakers combined with air core magnets, but also ensured safety, increased the operating efficiency of switching equipment, and was environmentally friendly.

Properties of SF6 Circuit Breaker

SF6 becomes a superior arc extinguishing medium due to the following specific physical and chemical properties.

Physical Properties

- Non-flammable, colorless, odorless gas.

- High dielectric strength: Has extremely good insulating properties.

- Heavy gas: Has high density and is heavier than air, helping to envelop the arc during operation.

- Liquefies at low temperatures dependent on pressure.

Chemical Properties

- SF6 gas is chemically stable and inert.

- Non-toxic: In its pure form, it is non-toxic and poses no danger to human health.

- High electronegativity, creating a strong affinity for free electrons.

- Quickly extinguishes the arc and easily regenerates for reuse.

- Non-corrosive.

Electrical Properties

- Excellent insulator, much higher than air, oil, or vacuum.

- High thermal conductivity.

- Requires little energy to extinguish the arc, helping to reduce wear.

- The frequency of the voltage does not affect the dielectric strength.

Advantages and Disadvantages of SF6 Circuit Breakers

| Advantages | Disadvantages |

| Has superior arc extinguishing properties, 100 times more effective than air. | The leakage of by-products created by SF6 gas during arcing is toxic to the environment. |

| Has high dielectric strength due to electronegativity. This strength increases with pressure. | Decomposed SF6 is very toxic. |

| Can interrupt large currents. | SF6 is an expensive gas, so SF6 circuit breakers are costly. |

| Compact design, requiring less space and installation cost. | The condition of SF6 leakage from connections must be continuously monitored. |

| Can handle all switching phenomena. | Requires special transportation and the gas quality must be ensured. |

| Has a sealed gas system with no leakage, so it can be installed in harsh environments. | SF6 is heavier than oxygen and can cause difficulty breathing. |

| Dielectric strength does not decrease because carbon particles are not formed. | The containment and recycling of SF6 gas require additional equipment. |

| Does not require expensive and bulky air compressor systems, except for the now-obsolete double-pressure type. | |

| No noise during operation. | |

| Non-toxic in its pure state. | |

| Non-flammable, so there is no fire risk. | |

| Low maintenance requirements. |

Structure of SF6 Circuit Breaker

The SF6 gas circuit breaker consists of two main components: the interrupter unit and the gas system.

- Interrupter Unit: The circuit interruption component consists of two types of current-carrying contacts: a fixed contact and a moving contact. The fixed contacts do not move, while the moving contact travels back and forth over a short distance. This component has a vent for the compressed SF6 gas to enter and exit, cooling the arc and extinguishing it.

- Gas System: SF6 is a very expensive gas, and the emission of product gases can be dangerous to the environment. Therefore, used SF6 is contained in a closed gas system for reuse.

In terms of detailed structure, the SF6 gas circuit breaker typically includes the following parts:

- Interrupter Chamber

- Insulating Bushing

- Support Column

- Tripping Spring

- SF6 Gas Pipe

- SF6 Pressure Gauge and Monitoring Unit

- Grounding Point

- Operating Rod

- Circuit Breaker Status Indicator Flag

Working Principle of SF6 Circuit Breaker

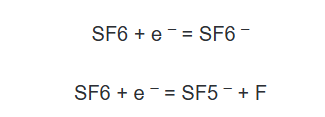

SF6 gas is compressed and stored inside a reservoir. When the circuit breaker interrupts the circuit due to an electrical fault, SF6 is simultaneously dispersed through the internal arc rings to the contacts where the electric arc occurs.

Essentially, an arc is the movement of electric charges containing free electrons. SF6 has high electronegativity, which absorbs free electrons to form negative ions. These ions are heavier and have low mobility compared to free electrons.

Due to the large mass of the negative ions formed, the movement of electric charges between the contacts is reduced. This increases the dielectric strength of the medium to extinguish the arc at zero current.

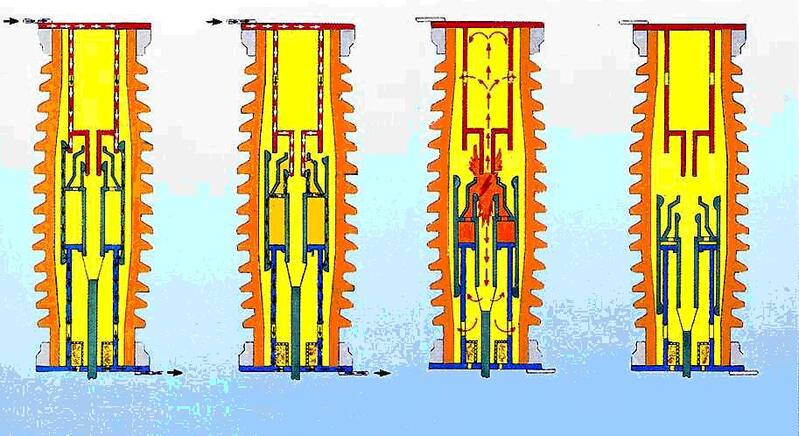

Direction of SF6 flow in a gas circuit breaker

After arc extinction, the decomposed SF6 quickly recombines back to its original state in the gas system. It is then recompressed into the high-pressure reservoir for reuse.

Sulfur Hexafluoride gas is only used for insulation and arc quenching. If the pressure of the SF6 in the contact housing does not meet the specified requirements, the arc quenching and insulation capabilities are not guaranteed. In this case, the SF6 gas needs to be refilled and checked for leaks.

Classification of SF6 Circuit Breakers

SF6 circuit breakers are divided into three common types: Pufferless type, Single-Pressure type, and Double-Pressure Puffer type.

Pufferless SF6 Circuit Breaker

This was the first type of SF6 gas circuit breaker invented, which does not include a puffer cylinder, meaning it does not rely on a high-pressure gas stream to extinguish the electric arc during the interruption process. This type of circuit breaker operates similarly to the principle of an air blast circuit breaker.

Structure

The Pufferless gas circuit breaker has a basic structure like conventional SF6 gas circuit breakers with two main parts: the gas chamber and the interrupter.

SF6 gas is compressed and stored inside the gas chamber. The gas chamber is connected to the interrupter via a valve. The valve is linked to the movement of the contacts. As soon as the contacts separate, the valve is opened to release the SF6 gas.

The arc extinguishing process occurs inside the interrupter or arc chamber. The interrupter consists of a moving contact and a fixed contact, both of which are hollow cylinders. The fixed contact has an arc horn surrounding it to control the arc. The tip of the arc horn is coated with copper-tungsten to increase resistance. The moving contact includes a vent. The vent is used as the outlet for SF6 gas from the arc chamber.

The moving contact, which travels back and forth, is attached to the actuator via an insulating rod that enables the entire contact assembly to move. The actuator is synchronized with the gas chamber's valve, releasing the gas in the same motion as the contact separation.

Working Principle

Under normal conditions, the contacts are closed, and the compressed SF6 is in the gas chamber. When a fault occurs, the moving contact begins to move and separates from the fixed contact. The surrounding environment of the contacts becomes ionized, and an arc is generated between the contacts.

At this point, the gas chamber's valve opens and releases SF6 into the arc chamber. The SF6 absorbs energy and immediately extinguishes the arc. Upon completing its task, the gas is recompressed and stored in the chamber for reuse.

Single-Pressure SF6 Circuit Breaker

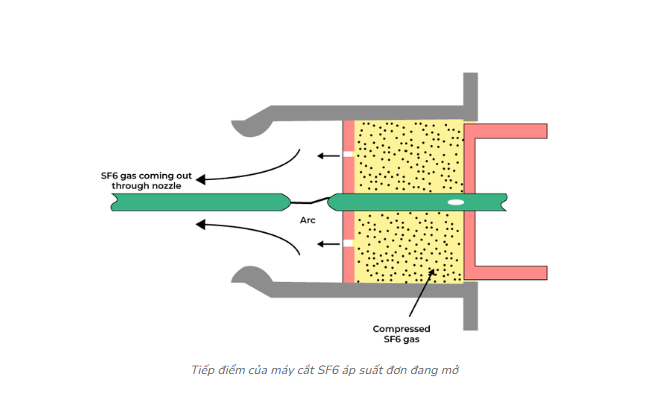

In the Single-Pressure SF6 circuit breaker, SF6 gas is stored at a high pressure of approximately 20 bar in a pressure vessel. The contacts are opened and closed by the movement of the operating rod.

Structure

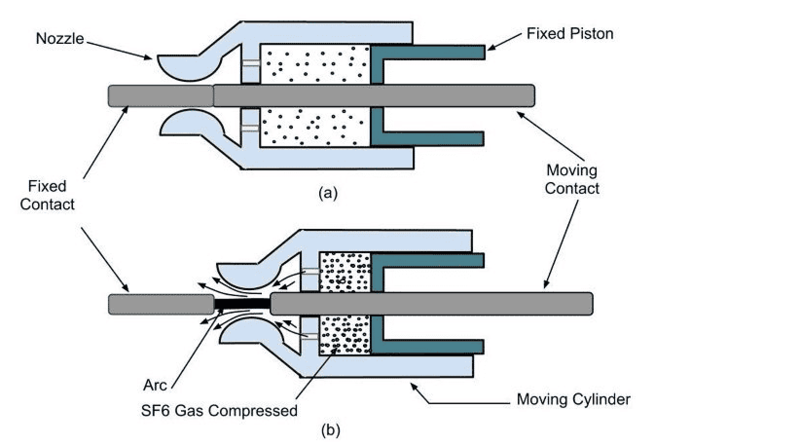

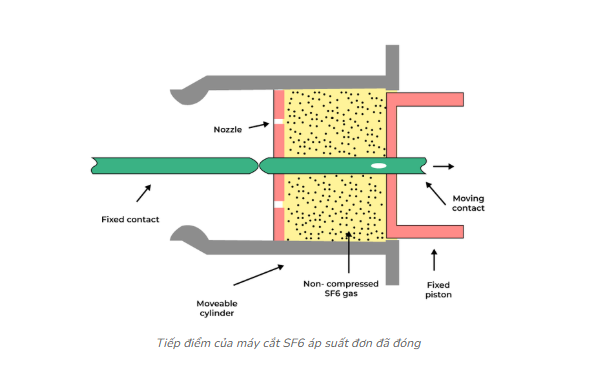

This type of circuit breaker has a more complex structure than the pufferless type, including a high-pressure SF6 reservoir, a puffer chamber, and an arc extinguishing nozzle. The fixed and moving contacts are located inside the puffer chamber.

There is a small gap between the two fixed contacts. A puffer cylinder is placed on top, filled with SF6 gas. When the cylinder moves, the volume changes due to the fixed piston. Inside the cylinder, there are vents for gas entry and exit. These vents are blocked by the fixed contact, which opens when the cylinder moves downwards. The hole inside the fixed contact is used for gas entry when the cylinder is in the closed position.

Working Principle

Under normal conditions, the puffer is in the closed position, and the contacts are also closed. The cylinder is filled with SF6 gas. Because the vents are closed by the fixed contact, the SF6 gas remains inside the cylinder.

When a fault occurs, the cylinder moves downwards to break the connection between the fixed contacts. The environment is ionized, and an arc is generated between the contacts.

Due to the downward motion and the stationary piston, the volume inside the cylinder decreases, compressing the SF6 gas inside. The vents open as the cylinder moves, releasing high-velocity SF6 through the vents. The arc is extinguished, and the contacts are fully opened.

Double-Pressure SF6 Circuit Breaker

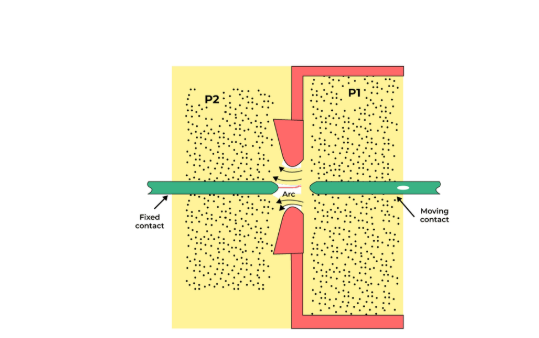

In the Double-Pressure SF6 circuit breaker, gas is stored at two different pressure levels: high pressure (approximately 20 bar) and low pressure (approximately 3-4 bar), allowing better control over the release of SF6 gas during circuit breaker operation.

Structure

The double-pressure puffer type SF6 circuit breaker has a more advanced design, including two pressure chambers: a high-pressure chamber and a low-pressure chamber. The fixed and moving contacts are located inside the high-pressure chamber.

The moving contact is hollow internally and contains a cylinder of compressed SF6 gas. The tip of the moving contact is designed to form a nozzle, which increases the gas velocity as it passes through the contact.

The fixed contact is designed to block the SF6 gas flow when in the closed position. When the contacts separate, the gas pathway opens, releasing the SF6 gas stream.

Working Principle

Under normal conditions, the connected contacts block the SF6 gas inside. When a fault occurs, the moving contact separates from the fixed contact and generates an arc. At this point, the high-pressure SF6 gas is released.

The pressure inside the cylinder is higher than the pressure outside, so the gas flows out. The nozzle helps to increase the gas velocity to quickly extinguish the arc. The SF6 gas is then filtered and stored in the reservoir for reuse.

Applications of SF6 Circuit Breakers

SF6 is a superior insulator, so SF6 circuit breakers are widely applied in high-voltage and medium-voltage electrical systems.

- Power Transmission and Distribution: Used in medium- and high-voltage power distribution networks to protect transformers, circuit lines, and other critical equipment, while maintaining a stable power supply across the entire system.

- Industrial Plants: Used in industrial facilities to protect electrical equipment from short circuit and overload conditions.

- Railways: Used in railway electrification systems to ensure reliable power distribution.

- Transformers: Isolating faulty units from the grid, minimizing the risk of damage, and preventing power supply interruptions to transformers.

- Switchgear Systems: The superior insulating properties and fast arc quenching capability of SF6 circuit breakers help maintain grid stability and prevent prolonged power outages.

- Renewable Energy: Used in renewable energy systems such as wind farms and solar power plants.

Comparison of SF6 Circuit Breaker and Vacuum Circuit Breaker

These are two types of circuit breakers with the same function of electric arc quenching; however, there are many distinct differences between these two devices.

| Criterion | SF6 Circuit Breaker | Vacuum Circuit Breaker |

| Arc Energy | Low arc energy (arc voltage is from 150 to 200V) | Very low arc energy (arc voltage is from 50 to 100V) |

| Contact Erosion | Due to low energy, contact erosion is not significant | Due to very low arc energy, contact erosion is very minimal |

| Arc Quenching Method | SF6 gas has excellent dielectric and cooling properties. After arc extinction, the decomposed gas molecules easily regenerate for reuse. That is, virtually no loss/consumption of the quenching medium occurs. Gas pressure can be monitored very simply and frequently. | No need for supplementary intermediate quenching measures. A vacuum chamber at a pressure of $10^{-7} \text{ bar}$ or lower is a nearly ideal arc-quenching medium. The arc-quenching chambers are sealed, so vacuum pressure monitoring is unnecessary. |

| Number of Short Circuit Interruptions | 10-50 short circuits | 30-100 short circuits |

| Number of Full-Load Switching Operations | 5000-10000 | 10000-20000 |

| Number of Mechanical Operations | 5000-20000 cycles | 10000-30000 cycles |

| Service Life | 5-10 years | 5-10 years |

| Maintenance Cost | High labor cost, Low material cost | Low labor cost, High material cost |

| Reliability | High | High |

| Dielectric Strength Between Contact Gap | High | Very high |

Some Questions about SF6 Circuit Breakers

Question 1: Is SF6 gas toxic to humans?

Answer: SF6 is chemically inert, so it is non-toxic to humans and animals. In fact, SF6 is used in medical diagnostics as an ultrasonic contrast agent or as a gas tamponade (to seal fluid flow) in ophthalmology.

Question 2: Is SF6 gas harmful to the environment?

Answer: SF6 does not deplete the ozone layer or cause air pollution. However, SF6 is nearly 24,000 times more effective than carbon dioxide ($\text{CO}_2$) at trapping heat, so it can be a very potent greenhouse gas. Therefore, SF6 levels in electrical switches must be monitored to detect leakage.