The recloser is a switching device, but it not only serves the function of switching and protecting the electrical circuit from faults, but also integrates many smart features of other equipment. So, what exactly is a recloser? What are the structure and operating principle of this device? Let's find out with us in the following article.

What is a Recloser?

A Recloser (or automatic circuit recloser) is an automatic switching device, capable of automatically closing the circuit after it has automatically interrupted the circuit due to a fault. Essentially, the recloser operates as an automatic electrical switch at the voltage level of 38kV. When a system fault, such as a short circuit or overload, occurs, the recloser will automatically check the line to determine whether the fault has been cleared. If it is only a temporary fault, the recloser will automatically reset and restore power.

The recloser was invented in the mid-1900s in the United States and first appeared commercially in the 1940s by Kyle Corporation. Early reclosers were simply oil-filled hydraulic switching devices integrated with basic protective relays. By the 1980s, the advent of solid-state relays (SSR) made reclosers more sophisticated, capable of handling a variety of line fault scenarios. Today's recloser series are upgrades of outdated versions, including solid dielectric insulation with a vacuum interrupter to interrupt the current and extinguish the arc.

The recloser is considered a perfect choice, significantly saving time and cost for power utilities; increasing revenue and reducing operating costs for factories and enterprises. The reason is that this device allows automatic power restoration, only after one or two momentary interruptions. For electrical faults requiring technician repair, the recloser minimizes the outage area and helps personnel quickly pinpoint the fault location, thereby minimizing the Momentary Average Interruption Frequency Index (MAIFI) and the System Average Interruption Duration Index (SAIDI).

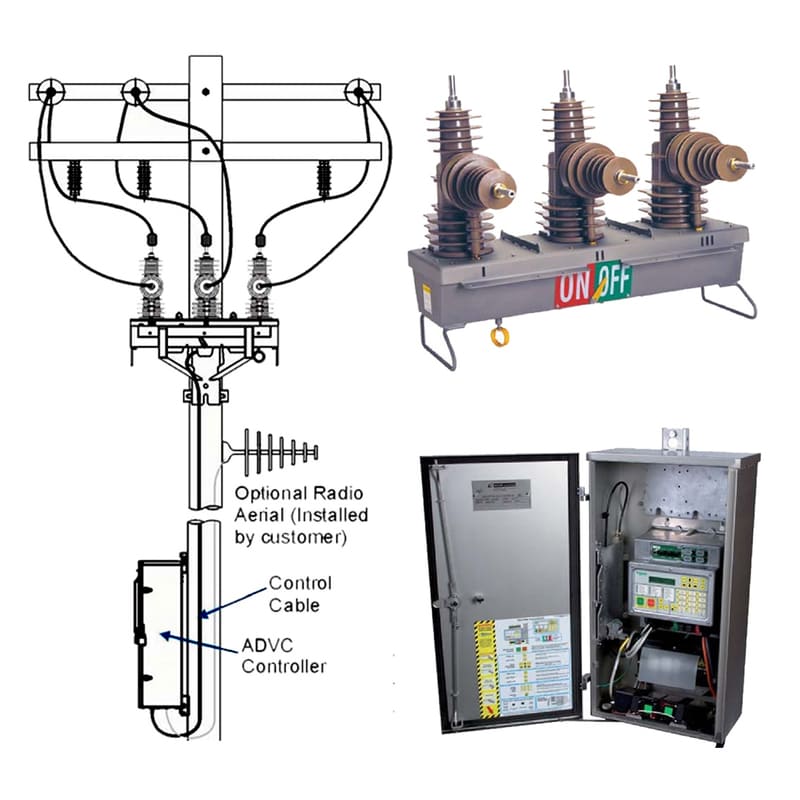

Structure of the Recloser

The essence of a Recloser is a smart switching device, so its basic structure includes a conventional circuit breaker accompanied by a control unit, which consists of electronic microcircuits allowing the programming of the number of trip-reclose cycles according to the fault characteristics. This control unit also performs the functions of metering, protection, fault data logging (P, U, I), line monitoring, system connectivity, and remote control.

A recloser is typically composed of three main parts: the interrupting system, the control system, and the operating mechanism.

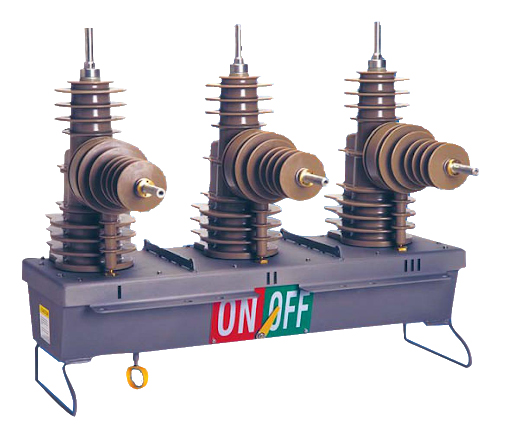

- Interrupting System: The component responsible for interrupting the current when a fault occurs. The recloser uses a vacuum interrupter to extinguish the arc, and SF6 gas or oil for insulation, ensuring system safety.

- Control System: Acts as the "brain" of the recloser, capable of fault detection, analysis, and making automatic switching decisions.

- Operating Mechanism: Is the link between the control system and the interrupting system. This component receives commands from the controller, actuates the recloser's switching mechanism, ensuring the circuit switching process occurs quickly and accurately.

Function and Operating Principle of the Recloser

On high-voltage lines, up to 90% of electrical faults are temporary, such as lightning strikes, tree branches falling onto wires, or electrocuted animals... and thus will clear quickly. In these cases, the recloser has the capability to determine the nature of the fault, then trip and reclose the circuit. If the fault persists, the Recloser will continue to open and close the circuit up to the initial programmed limit.

The operating principle of the Recloser is demonstrated in the following sequence:

- Fault Detection: When a short circuit or overload fault occurs on the line, causing a sudden increase in current, the internal sensor of the Recloser will immediately detect it.

- Instantaneous Trip: The Recloser will quickly trip the circuit to isolate the faulty element. This operation occurs almost instantaneously to minimize the impact of the fault on equipment and lines.

- Reclosing Cycle and Time Delay: After tripping, the Recloser will wait for a specific time delay (usually pre-set) and then automatically reclose the circuit. The time delay allows temporary faults to self-clear.

- Cycle Repetition and Lockout: If the fault still persists, the Recloser will continue to execute subsequent reclosing cycles. The subsequent cycle has a longer time delay than the previous one, allowing more time for fault clearance. The Recloser is typically programmed for 2 - 4 automatic reclosures. If the fault is still not cleared, the Recloser will lock out completely until human intervention is required.

Upon the clearance of the fault, the recloser provides important data such as power values (W, VAr), voltage (V), current (A), or frequency (f), supporting transmission grid operation, and analyzing fault history to prevent similar risks.

With such a smart operating principle, the Recloser not only has the function of a switching device but also integrates the functions of many other pieces of equipment:

- Overcurrent and overvoltage protective device

- Frequency protective unit

- Automatic circuit-closing sensor

- Line safety monitoring device

Installation Location and Operating Conditions of the Recloser

The recloser is used throughout the entire power distribution system, from substations to residential utility poles, including small reclosers for installation on single-phase power lines up to three-phase reclosers used in substations and on high-voltage lines up to 38kV.

Installation and Operating Conditions:

- Ambient temperature from above $-45^\circ C$ to below $+85^\circ C$

- Air humidity not exceeding 90%.

- Maximum installation altitude of 3000m above sea level

- Installation location without frequent strong vibrations

- Ensuring lightning protection capability for the equipment

- The pole foundation must be designed and constructed securely

Notes during Operation:

- Operation Monitoring: Regularly monitor operating parameters such as current, voltage, frequency... to promptly detect and handle abnormal incidents.

- Periodic Maintenance: Perform regular cleaning of insulators, checking insulation oil, tightening connections, etc., of the Recloser to maintain operating efficiency and extend lifespan.

- Fault Handling: When a fault occurs, it is necessary to quickly isolate the recloser from the system, determine the cause, and proceed with timely repair or replacement.

Classification of Recloser Circuit Breakers

According to the most common classification, based on the voltage phases of the system, Reclosers are divided into three types.

Single-Phase Recloser

Single-phase reclosers are used to protect single-phase lines such as branches or taps of a three-phase feeder. When an earth fault occurs, one phase can be interrupted, while power on the other two phases is maintained.

Due to their light weight, single-phase reclosers are often installed directly on poles or individual substations using integrated mounting brackets. This type of recloser can be controlled by a hydraulic control unit (integrated within the recloser tank) or an electronic control unit (housed in a separate enclosure) depending on the manufacturer's design.

Three-Phase Recloser

Three-phase reclosers are used on three-phase circuits to interrupt all three phases simultaneously in case of electrical faults. The selection of a three-phase recloser is based on criteria: rated current, tripping mechanism, insulation medium, or the choice of hydraulic or electronic control.

In European-style transmission networks, three-phase reclosers have the capability to withstand issues with AC currents and self-interrupting faults.

Single-Three Recloser

This type of recloser is controlled by an electronic control unit with three operating modes:

- Three-Phase Trip and Three-Phase Lockout: All 3 phases are tripped and reclosed sequentially.

- Single-Phase Trip and Three-Phase Lockout: Each phase operates independently to trip overcurrent and reclose automatically.

- Single-Phase Trip and Single-Phase Lockout: Each individual phase will trip and sequentially lock out independently of each other.

Applications of the Recloser Circuit Breaker

The recloser is an indispensable device in modern electrical systems, playing an important role in ensuring continuous and stable power supply.

Some main applications of the recloser circuit breaker:

- Protection of medium-voltage current

- Reducing fire and explosion risks on the line with the capability to protect against earth faults at the 500mA level, eliminating 80% of fire and explosion risks

- Increasing the automation level of the power distribution network

- Protection of substations in rural or sparsely populated areas

- Protection against single-phase overcurrent in a three-phase circuit

- Protection of downstream mobile equipment in a three-phase circuit

Frequently Asked Questions about Recloser

Question 1: How is a Recloser different from an LBS (Load Break Switch)?

Answer: A Recloser has the capability to automatically reclose the circuit after clearing a fault, which the LBS does not have.

Question 2: Where is the Recloser typically installed?

Answer: A Recloser can be installed at any location on the transmission grid that is compatible with the device's rating, such as: main distribution substations, main distribution lines, or branch lines from the main distribution trunk to protect the main line when a fault occurs on the branch line.